Physical Isolation | Safety & Environmental Protection

Features a fully enclosed housing for physical isolation, effectively containing ink mist and collecting VOC gases. Equipped with an exhaust system (requires external connection) for filtered or catalytic treatment, reducing environmental impact and ensuring operator safety.

- Full enclosure with sealed design effectively captures VOC emissions for centralized treatment - ensuring eco-friendly operation and workplace safety.

- Blocks UV scatter to prevent skin/eye damage to operators

- Maintains stable internal temperature/humidity by reducing external airflow and dust interference

Multi-Functional Safety Modules

C3200 features Interlock safety control, printhead collision guards, and automatic ink shortage alerts to enhance safety, operational efficiency, and print quality.

- Interlock safety control with precise sensors ensures immediate shutdown when the cover is opened for safe operation

- Printhead collision guards provide physical buffering or trigger shutdown to protect delicate components like printheads and rails

- Automatic ink shortage alerts notify operators to replace or refill ink, preventing print interruptions and printhead damage

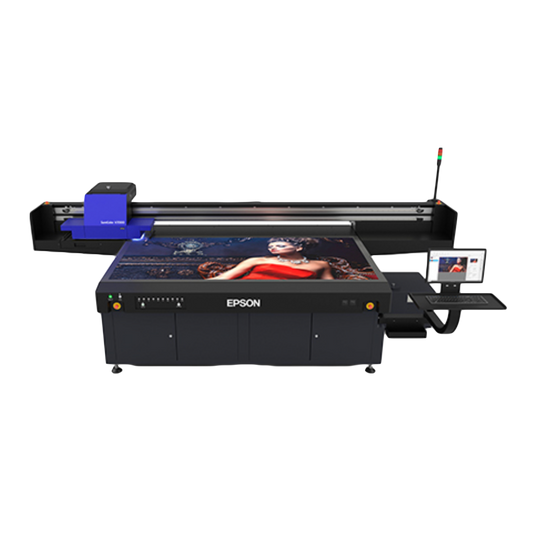

User-Centric Design

Ergonomic design with handles and foot pedals, dual-sided operation panels with displays, optimized workflow for superior user experience.

- Dual-side control panels boost production efficiency

- Tri-color status lights for real-time operation monitoring

- Smart vacuum system adapts to various materials (no wrinkles on soft media, no warping on rigid substrates) for effortless printing